Propeller

The efficiency of a propeller takes an important place in the design process of the propulsion because its efficiency and the ship’s fuel consumption are directly related.

The efficiency depends on …

- The shape of the ship’s underwater body

- The power delivered to the propeller

- The number of blades

- Rotations per minute

- The maximum propeller diameter

- The blade surface area and smoothness of the blades

- The ship’s speed

Every propeller is designed individually based on the specific demands set for this propeller. As a result of this, there is a large variety in shapes of blades. Other issues to consider in propeller design are …

- Cavitation resistance

- Turning direction

The propeller blades have a fixed position. As a consequence the direction of rotation of the propeller has to change if the ship stops or must go astern. This is realised with a reversing clutch or a reversible engine.

We represent Nakashima Propeller from Okayama, Japan.

Fixed Pitch Propellers

With its integrated technologies, Nakashima provides high-performance and high-quality propellers by optimally balancing propulsion efficiency, strength and vibration performance according to each customer’s special requirements with special focus on …

- Built to order creation of optimum products

- Design and analysis technology

- World-class propeller factory

NHV Effect

Because of Nakashima’s unique technology, hub vortex causing energy loss and rudder erosion can be reduced by using specially shaped propeller blades, without the use of any special accessories. Reduced hub vortex improves efficiency and prevents rudder erosion.

NHV Effect

Conventional Type

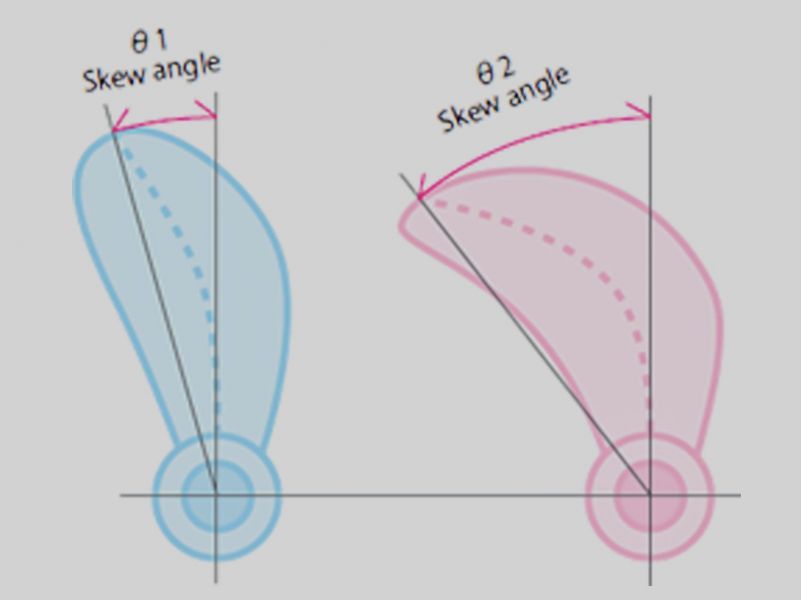

High Skew Effect

Propellers with a sharp sweepback are called “high skew” propellers. Their unique shape reduces the vibration of a vessel's body as well as propeller noise.

Keyless Propeller

With keyless propellers, no key is used to connect the rotating shaft and propeller. When the propeller shaft is press fit into the shaft hole of the propeller, the contact part becomes completely joined under specific conditions. Once the shaft and propeller are joined, the propeller is completely attached without being pressed back from the shaft. Since keyless systems are extremely reliable, most large-size merchant vessels use keyless propellers.

Nakashima designs and manufactures environmentally friendly high-efficiency controllable pitch propellers. Our controllable pitch propellers developed utilizing the expertise and advanced technology accumulated in the development of fixed pitch propellers have been delivered to many customers in Japan and other countries.

Features

- Enables the required vessel speed or thrust force to be obtained, even on vessels where load conditions vary greatly such as trawlers and towing vessels.

- Avoidance of over torque condition of the main engine by reducing the propeller pitch angle during operation in rough weather compared to regular operation.

- Enables efficient operation of the main engine output and minimization of fuel consumption.

- Efficient operation, high stopping performance, and shorter time spent when leaving the shore or docking due to continuous movement from full forward to full reverse.

- Reduced fuel consumption by operation at the optimum efficiency point where propulsion efficiency, fuel consumption of the main engine, and other factors are comprehensively considered.

- Enables the required vessel speed or thrust force to be obtained, even on vessels where load conditions vary greatly such as trawlers and towing vessels.